Equipment Overview

Our facility is equipped with advanced machinery to handle complex projects with precision and efficiency. We use state-of-the-art technology to ensure the highest quality in every component.

Lathes

Our lathes are designed for precision turning and are capable of handling a wide range of materials, providing flexibility and accuracy in production.

Mills

Our milling equipment includes 3-, 4-, and 5-axis centers that allow for detailed and complex machining processes, ensuring high precision and quality.

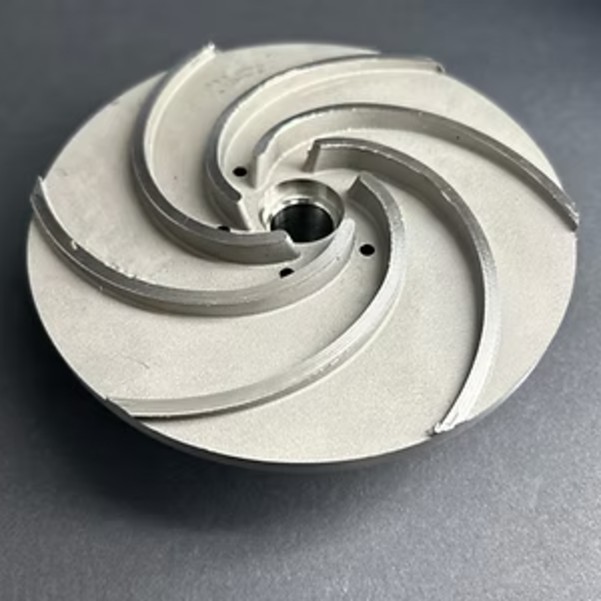

Millturns

The millturn machines combine the capabilities of both milling and turning processes, allowing for efficient production of intricate parts with tight tolerances.